-

-

-

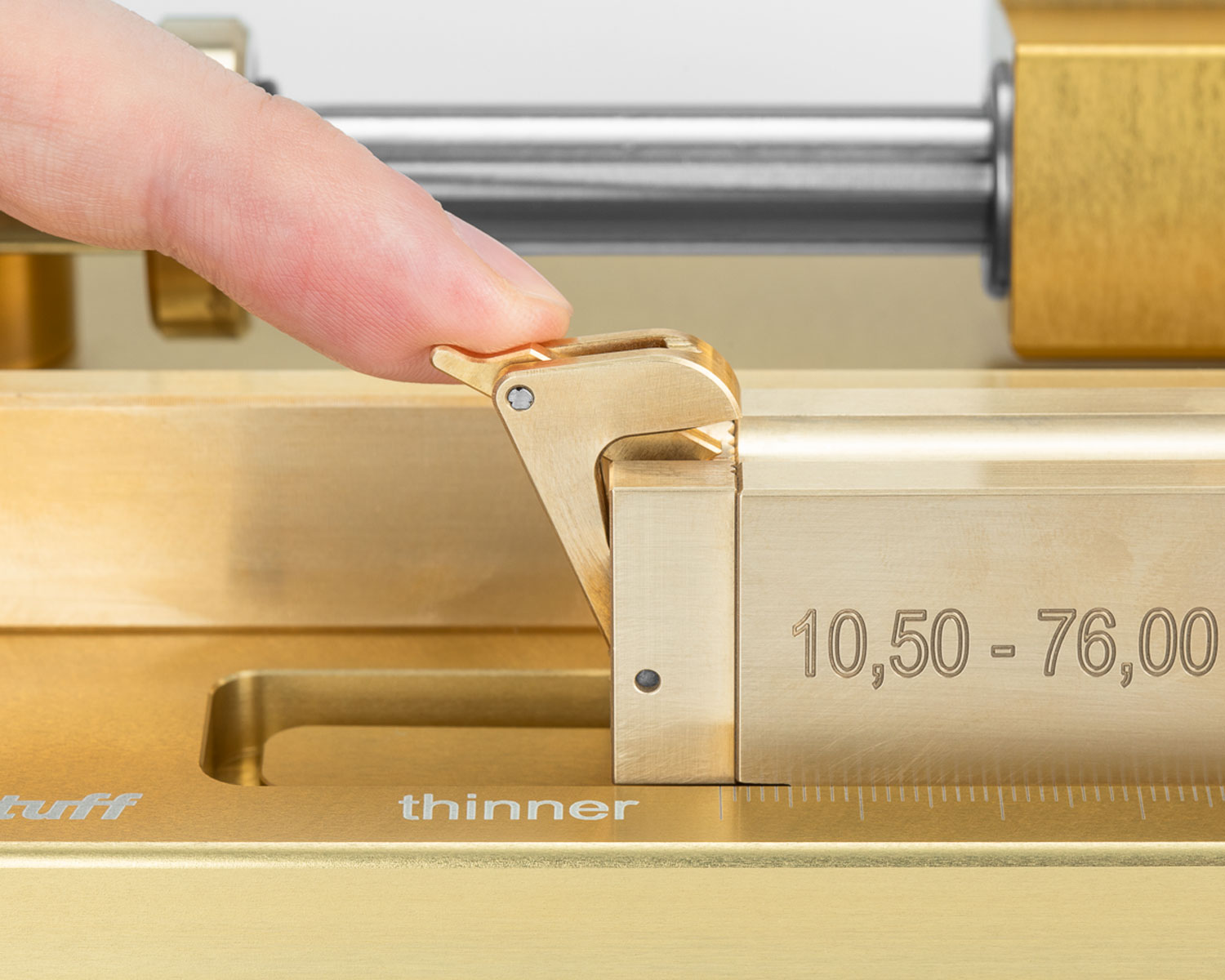

Pushing from the top outside corner of the cane holders, push the holders outwards until they lock into position outside the cane bed.

-

-

-

-

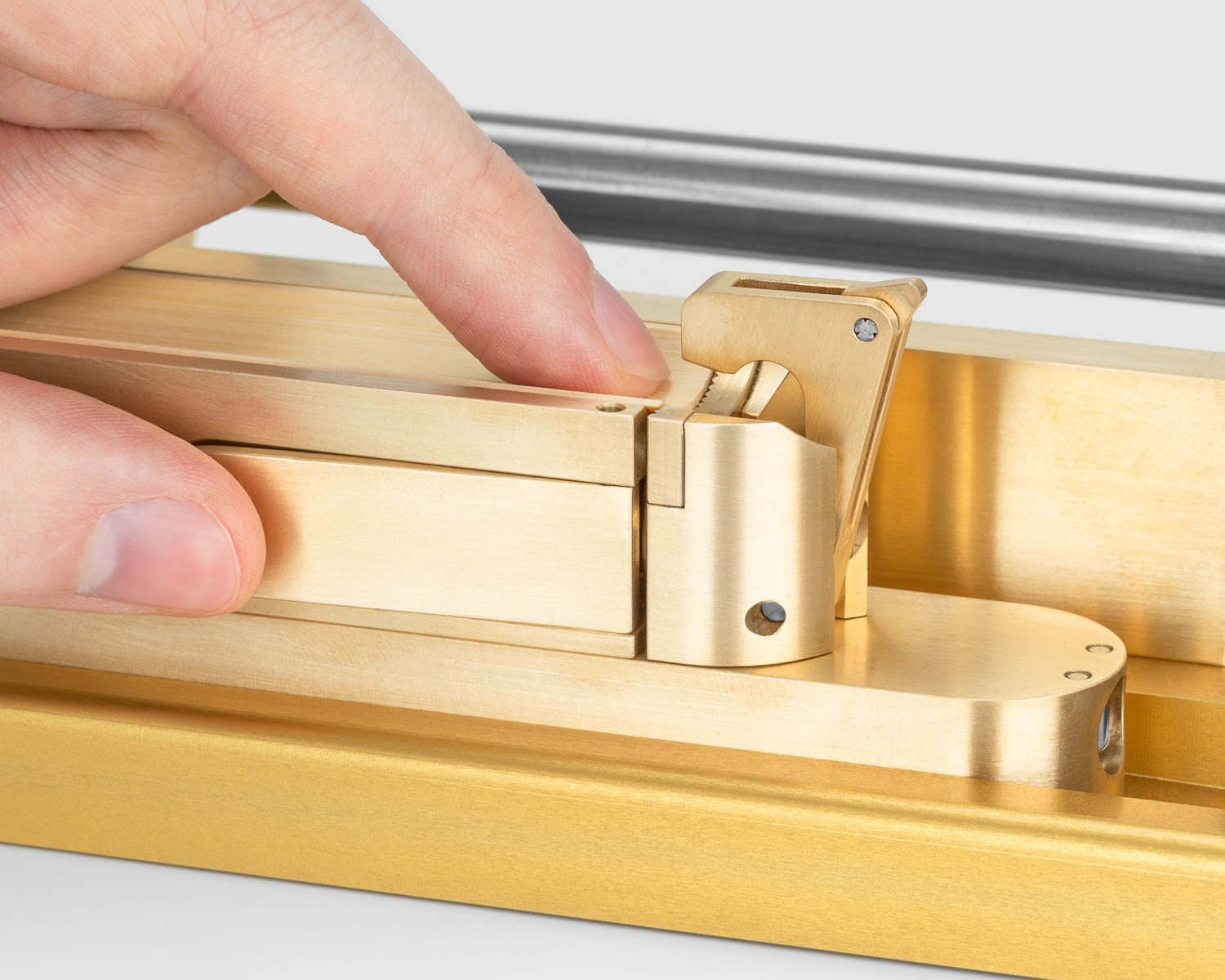

Press the lever towards the right side on the front of the cane bed; this will open the clamp. Place the cane into the cane bed, center it, and push firmly down on the cane before releasing the clamp lever.

-

-

-

-

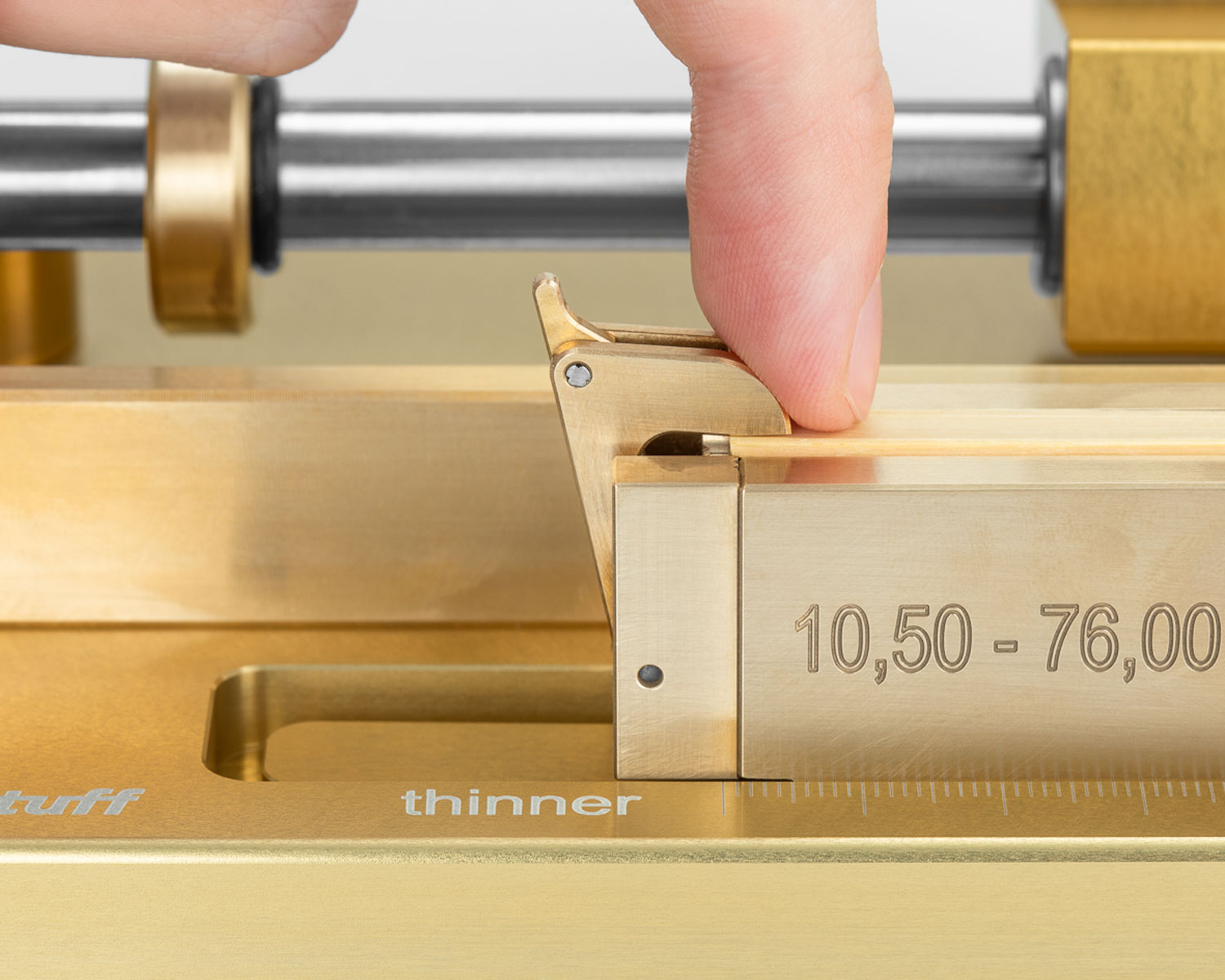

Push the cane holders outwards from the inward-facing sides so that the locking mechanisms release, and the cane holders are holding the cane down to the bed.

-

Figure Machine

pending

Figure Carriage

pending

Using the Gouging Machine

Lower the carriage to the cane between the cane holders, taking care that the blade does not come in contact with the cane holders. Draw the carriage of the gouging machine holding the blade to the far right-hand side of the gouging machine. Always begin the gouge stroke at the very end of the cane. Push the carriage all the way to the left-hand side of the gouging machine to gouge the cane. Repeat this process until no more cane is removed by the blade.

At this point we recommend marking the center of the gouge at each end of the cane with a pencil. This will be helpful when aligning the cane for shaping and profiling, ensuring the reed is symmetrical throughout the entire process. The locking arms of the cane holders cane be used as a reference guide for this.

Release the cane by pushing the cane holders back into their locked position, press the lever, and remove the cane from the cane bed.

CAUTION

Take care to always push in the direction of the gouge, and not downwards. Shaving cane off layer by layer will produce more consistent results than trying to force the gouging machine to remove as much cane as possible quickly.

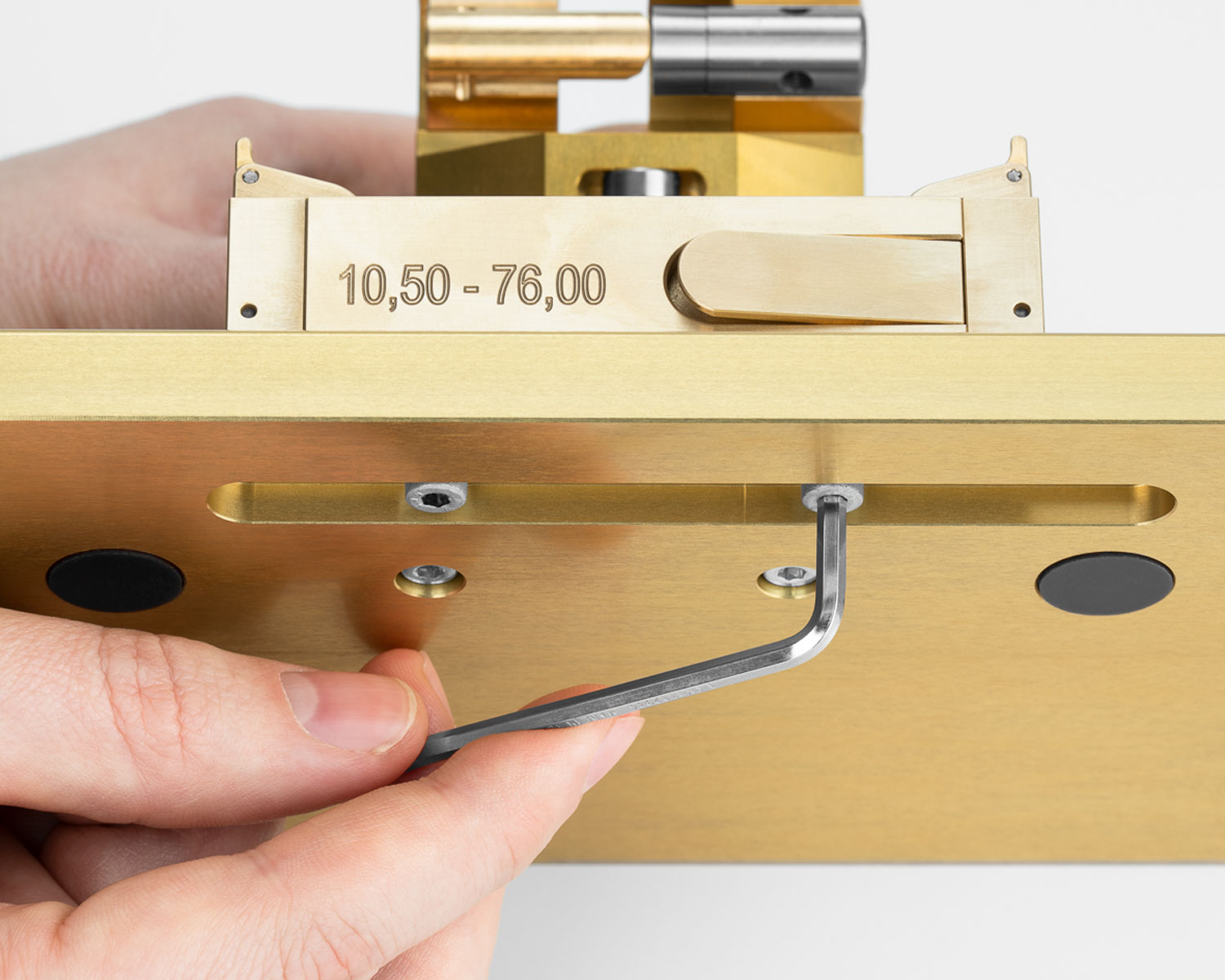

Adjusting the Thickness

To adjust the thickness of the gouge start by loosing the screws of the cane bed from underneath the machine. The cane bed can then be slid left or right, closer to "thinner" or "thicker" on the scale. Once the new position has been reached, simply tighten the screws again and you are ready to gouge at your new thickness.

Adjusting the Shaving Thickness

To adjust thickness of the shavings, turn the screw on the left face of the blade carriage. This is the screw that extends towards the blade and is pressed against the brass limiting bar. Tightening this screw will decrease the shaving thickness, whereas loosening it will increase the shaving thickness.

Another factor to consider when adjusting the shaving thickness is the distance between the blade and the limiting bar. We recommend a distance of about 1.5 mm.

Rotating the Blade

If the blade is becoming dull, loosen the screw at the top of the carriage. This will allow you to rotate the cylindrical blade to a new position that is still sharp. Insert the screw into one of the pre-drilled holes and tighten before continuing gouging.

Exchanging the Blade Set

Centering the Gouge

This gouger is designed to allow you to re-center the gouge should it come out of alignment for any reason. The goal is to have the gouging axle be exactly parallel with the cane bed.

Basic Adjustments

Position the blade carriage at one end of the cane bed. Loosen the top set screws on the towers holding the axle with the largest hex key. Then insert the hex key into the screw at the base of the tower on the same side of the machine as the blade carriage is placed and turn the screw as follows to adjust the positioning:

COUNTERCLOCKWISE: Blade moves away from the axle = thinner gouge on the side of the cane opposite the axle.

CLOCKWISE: Blade moves towards the axle = thinner gouge on the side of the cane

nearest the axle.

This process is the same, and needs to be repeated, at each end of the cane bed. When adjusting the position towards the right end of the bed use the adjustments screws at the right end of the machine, and vice versa.

After ensuring the blade is centered, tighten the top set screws on the towers.

CAUTION

After changing the setting – check the glide of the blade. It should not cut into the end of the bed, otherwise you will ruin the blade or the machine!!

Checking for Center

To check if the blade is centered, fully gouge a piece of cane. Before removing the cane from the bed, take a pencil and draw on the cane making sure to cover the entire surface.

Tip: also be sure to mark the center at each end of the cane to help align the cane later.

Remove the cane, rotate the same piece so the end that was on the right-hand side is now on the left-hand side and place it back onto the cane bed. Take another pass with the blade carriage.

If the pencil marks are removed only on the side closest to the axle, then the blade will need to be adjusted further away from the axle using the steps described above.

If the pencil marks are removed only on the side further away from the axle, then the blade will need to be adjusted closer to the axle using the steps described above.

If the pencil marks are not removed, or are removed evenly, then the blade is centered an no further adjustments are necessary.

Maintaining your Gouging Machine

Be sure to dry and clean the machine after use. Regularly check the blade and machine for damage, and oil the axle and blade with a small amount of oil to ensure a long life for your Reeds ‘n Stuff gouging machine.

Safety Instructions

Please always be careful while using your Reeds 'n Stuff product. The blades used in our machines, and reed making in general, are very sharp and may cause injuries and other damage.

In order to avoid negative consequences, you should follow the following safety instructions during installation, usage and maintenance of your machine:

Reeds 'n Stuff products are not a toys. They are therefore not to be used by children and persons with limited physical, sensory or mental abilities.

Reeds 'n Stuff products are intended to be used indoors.