You can pay by credit card, Veem or Paypal. In some counties of the EU you can also pay in advance, by direct debit or on account. For payments by Veem, please contact us.

All possible payment methods will be displayed depending on your invoice and delivery address.

We will ship your order if all items are in stock. Some articles need to be mounted.

In some cases we will produce articles individually. This is noted on the concerned article page.

As soon as your order is ready to ship you will be informed by us or the shipping company (UPS or DHL).

Your purchases will be taxed using the applicable VAT tax rate for your country.

Please leave a note in the cart message field if you need a tax free form.

You can choose another delivery address during the payment process.

Delivery time is usually between 6 and 14 working days. In some cases - especially areas which are difficult to reach or due to customs reasons - delivery can be delayed. It is not recommended to place an international investigation request before 8 weeks after shipping.

Payment must be made in advance including the order number. Delivery can be made as soon as the payment has been cleared. We will send the account information with the confirmation email.

Please make sure the money transaction is without fees for us. We will not send the merchandise if you split the cost for transaction or the bank fees.

The purchase value for redeeming the voucher has not yet been reached. There may be products in your shopping cart that are not eligible for discount. Discounts are valid for most products of Reeds 'n Stuff. Discounts are not assigned to items like books, reeds, tube cane, processed cane, industrial gouging machines, customized products, shipping costs and payment fees. Such items are marked by "**" in your cart.

Sharpening Your Knife

Do not grind your blade, grinding can over heat and damage the temper of the steel of your knife. Use honing oil with your whetstone; this will help keep your stonefree of shavings that can clog the pores of the stone and make it less effective. A quality, natural whetstone is all that is needed to sharpen your knife unless you damage the edge and are forced to take off a lot of steel. In such cases is recommended that you use a bonded abrasive to begin your sharpening process.

A common honing angle for a sheath knife is between 20 and 30 degrees. The larger the angle the tougher the edge. Maintaining a consistent angle is the critical factor in honing your edge; to small an angle makes a weak edge which will dull rapidly. An angle much less than 20 degrees will make the edge so thin as to bend the knife edge slightly under honing pressure and therefore it cannot really be made sharp.

1. Place some honing oil on the stone, never use it dry. The oil will keep the steel shavings from clogging the pores of the whetstone. For the “De Luxe” stone only use water.

2. Lay the blade across the hone as illustrated, tilting it to the desired honing angle and draw the blade across the hone in a slicing motion, sweeping the length of the hone so that the whole blade from guard to tip is passed over the hone in one motion.

3. Turn the blade over and again till to the same honing angle and repeat the same motion as in step 2.

4. Take equal numbers of strokes for each side of the blade to maintain a balanced cutting edge.

5. If you are establishing an edge on a new knife or re-establishing an edge on a damaged knife, honing may take quite a long time. Once you have achieved the edge and sharpness desired, you knife edge can be maintained with very little effort as long as you do not damage or wear it down severely. It may be necessary to use manmade bonded abrasives to hone damaged knives with nicks, broken or when establishing a new edge.

6. After you knife has been honed, clean your whetstone by applying more honing oil to it and rub with your fingers then wipe off excess oil with a clean cloth. You can wash away the remaining oil if desired with soap and water.

7. The last step is the stropping. Please clean your blade with a soft tissue before. Draw the blade edge along the leather with slight pressure. First, use the abrasive leather side with the blue packed abrasive paste. Then you can straighten and polish the blade with the fine leather side.

The purchase value for redeeming the voucher has not yet been reached. There may be products in your shopping cart that are not eligible for discount. Discounts are valid for most products of Reeds 'n Stuff. Discounts are not assigned to items like books, reeds, tube cane, processed cane, industrial gouging machines, customized products, shipping costs and payment fees. Such items are marked by "**" in your cart.

We also accept payments by Veem. Veem is a business to business payment method which makes international payments more simple.

Your payment can be processed within 1 – 3 days. Thus we can ship your order faster than with common wire transfers.

You need an veem account to send payments by veem. You can register on Veem.com.

In order to help you to choose the matching template please send us pictures of your reeds.

-

-

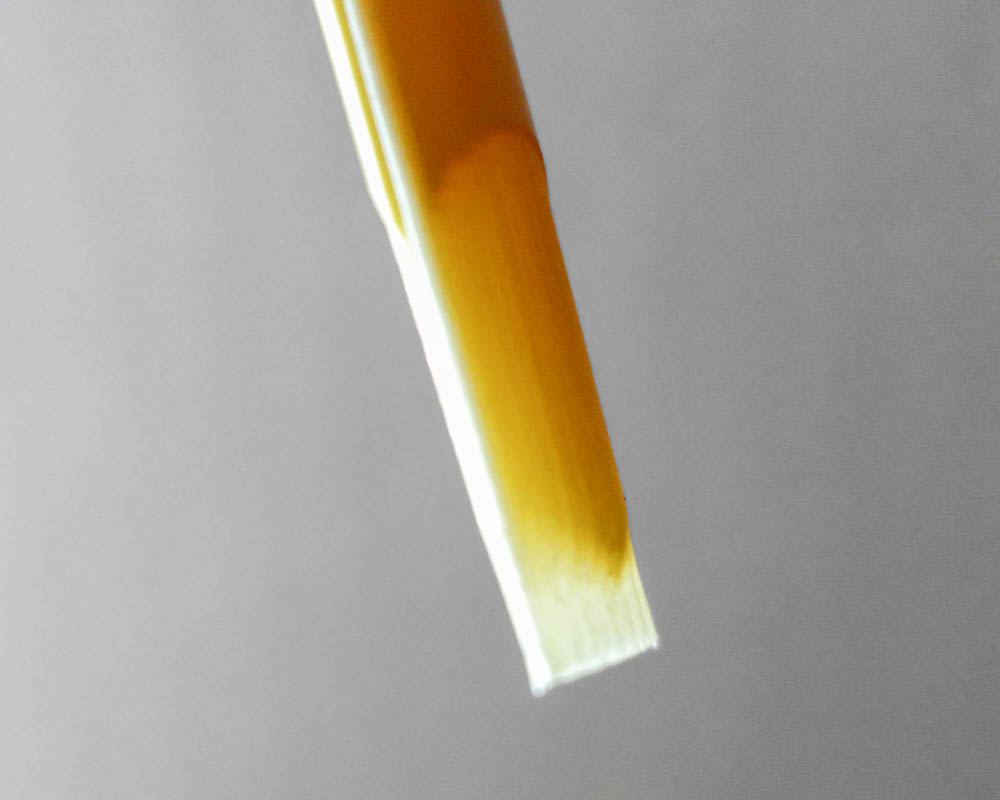

Front view against the light

-

-

Side view

Further information can be helpful: The typ of your instrument and bocal.

This will allow us to choose the matching template for you.

How you change the battery of your digital hardness tester or dial indicator.

The battery needs to be changed when the dial is flashing, dull or the battery sign appears. The battery is covered by a lid on top of the indicator on the left side.

-

-

Open the lid with a crew driver.

-

-

Take out the battery holder carefully.

-

-

Make sure you will remember the correct position.

Hint: A photo from your smartphone will help you not forget the positioning of the battery holder and the battery.

-

-

On the battery you will find information about the type of battery used (e.g. SR44).

-

-

If possible, do not touch the new battery with your fingers. Use a piece of cloth.

-

-

When inserting the new battery be careful to not damage the contacts – the little metal parts inside.

Unfortunately for hygienic reasons, the return of reeds is not possible.

How can I order templates for a trial?

You don't know which template suits you? Don't rack your brain. Simply ask us for several options and test them.

-

-

Add your templates to your cart.

You will be informed on the article page, if an article is available for trial.

-

-

Complete your online order.

-

-

After you received your order you can test templates within 60 days.

-

-

Choose the items you want to keep,

send back the items you do not want.

-

-

When you return the product in good condition within 60 days we will pay back the price of the product minus the test fee and shipping costs, if applicable.

With digital invoices you can simplify and speed up your internal processing. As every company uses different processes, we want to ensure that the e-mails with the invoice as a PDF are sent directly to the correct account.

The correct email address for invoicesWe have saved your general business e-mail address in your customer account. This e-mail address is used only for sending invoices. You can name a separate e-mail address at any time to which digital invoices are to be sent.

To change your billing email address or add another email address, please contact us at buchhaltung@reedsnstuff.com.

2 Years Warranty

Reeds 'n Stuff product are warranted for the period of 2 years.

Excluded are blades and wear and tear parts.

The warranty is only valid if, when warranty service is

required, the warranty card is fully and properly completed or/ and is

presented with the original invoice.

How to Order a Resharpening

-

Order

Order the amount of your blunt blades on our webshop.

-

Send

Send your blades to:

Reeds 'n Stuff GmbH

Karlsbader Strasse 88 c

09465 Cranzahl

GermanyPlease include a copy of your order or note your order number.

Please note that import charges will be added by the shipping service provider if you have not indicated on the customs document the contents of the shipment or if the amount was stated too high.

-

Receive

After we received your blades we will resharpe and return them to the given delivery address.

The blades can be resharpened over and over again until they are too short for the machine. When you send your blade to us to be resharpened you will not receive exactly this blade back, but rather another which has already been resharpened. This allows for a quicker turnover as the blades can be resharpened in batches rather than individually.

Is blade resharpening also offered for Passin Gouging Machine?Unfortunately, we do not offer the blade resharpening service for Passin Gouging Machine. To achieve satisfactory gouging results again, simply order a new blade and replace it.

We are always eager to provide the best quality possible.

Since cane is a natural material, we can not always completely eliminate inaccuracies.

The gouged and shaped cane is carefully examined and checked for the correct thickness at several points using a Reeds 'n Stuff dial indicator with a tip K.

Depending on which dial indicator and tip you are using, there may be minimal variations in the measurement results.

It is also possible that the cane changes slightly after leaving our workshop, depending on the climatic conditions.

However, if you ever feel that the cane does not match your order, please feel free to contact us.

There is a security method required for your credit card payment.

Please contact your bank or use another payment method.

The 3d security authentication is mandatory for payments in the EU since January 1st, 2021.

Usually you receive a temporary pin by message or a security app by your bank.

The “On Demand Delivery (ODD)” service from DHL Express is an innovative solution to minimize failed delivery attempts. As a customer, you will always be informed of the expected delivery date via e-mail notifications. In addition, ODD offers the flexibility to choose between five different delivery options via the dedicated On Demand Delivery website to customize the delivery according to your needs.

-

-

Delivery on Demand

You select a new delivery date and/or a new time slot. The new delivery date can be up to 7 days after the original date.

-

-

Neighborhood Delivery

You designate a neighbor who can accept the shipment for you. Inform DHL Express of the name and address of the neighbor (up to two houses away from the original recipient address or on the opposite side of the street).

-

-

DHL Service Point pick-up

Simply select a DHL Express Service Point near you. The nearest Service Point will be displayed on a map: DHL Service Center, Partner Service Points & Packstations. If you change the zip code, you will see DHL Service Points in other regions.

-

-

Alternative Delivery Address

You can redirect the shipment to an alternative address (e.g. to your place of work). The new address must be in the same country of destination as the original address.

-

-

Vacation Storage

If you are on vacation at the expected time of delivery, you can specify a new delivery date and/or time window via ODD. The new delivery date can be up to 30 days after the original delivery date.