-

-

-

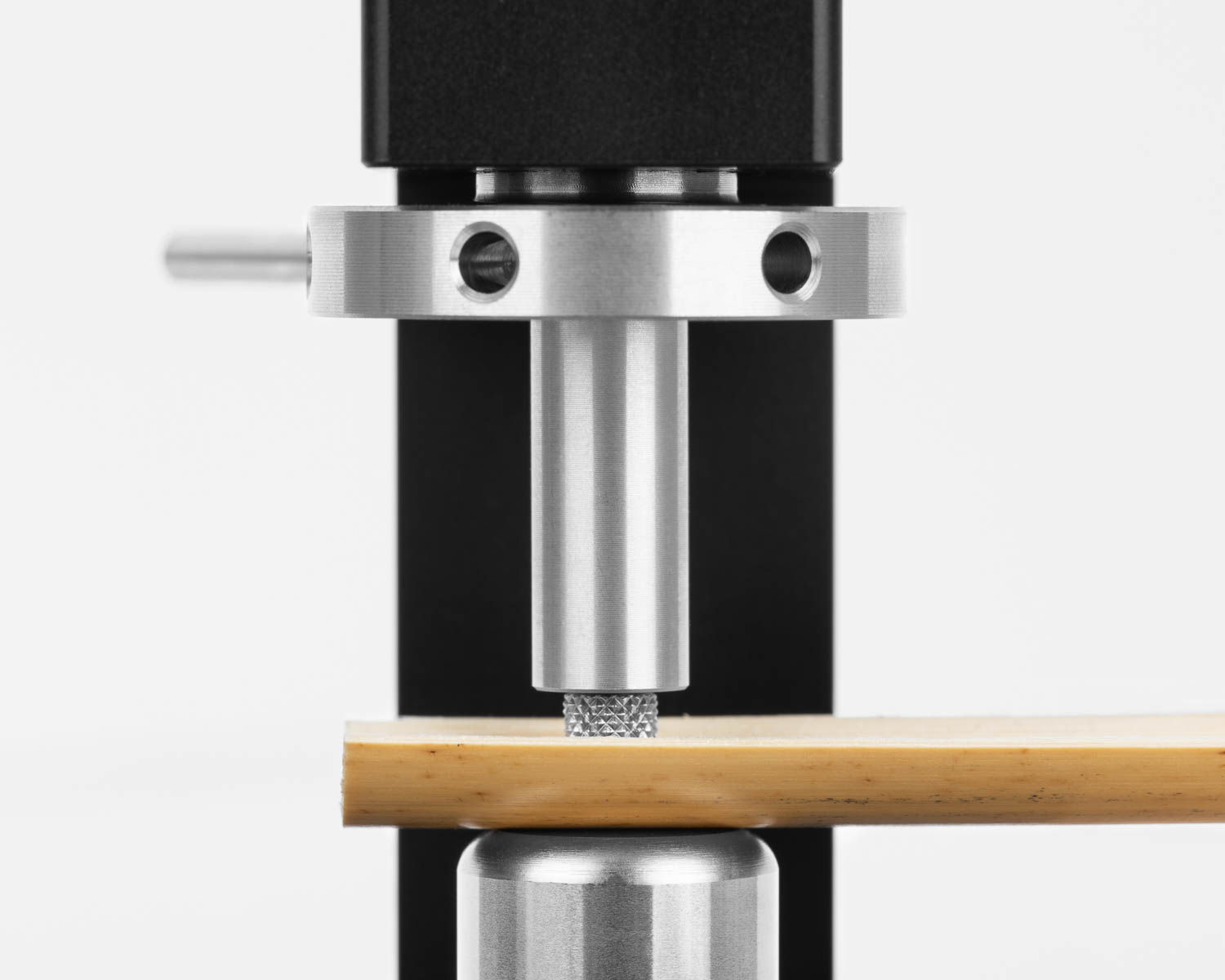

Insert the cane as shown between the arbour and the measuring tip. The tip should be about 1 cm from the end of the cane.

The rotating handle should be on the right side of the hardness tester

-

-

-

-

Zero the dial

Turn the rotating handle from the right side to the left side of the hardness tester.

-

Figure Machine

pending

General Comments

The purpose of hardness testing cane is to discern differences between pieces of cane and select those pieces which have the greatest potential for making excellent bassoon reeds.

Many reed makers sort cane into categories of hardness that are more appropriate for different styles of reeds. Others find a range of cane hardness that matches their style of reed making and only use this cane. Cane that is too hard or too soft is unlikely to become a useful reed. This will save you from investing time in a piece of cane that is unlikely to be useful, allowing you to maximize the return on your time investment.

To ensure consistent readings over time we recommend hardness testing your cane within the same environmental parameters (i.e. similar room temperature, humidty, etc.). Testing cane in a cold room versus in a warm room may result in variations in the measurements from the same piece of cane.

For digital hardness testers, we recommend always using the metric readout, as these measurements will be more in line with the readings from the analog hardness tester.

Using the Hardness Tester

After waiting 2 - 3 seconds for the measuring tip to settle, the hardness can be read off of the dial. Turn the rotating handle back to the right side of the hardness tester before attempting to remove the cane from the hardness tester.

Be sure to test the hardness at both ends of each piece of cane. The average of these two numbers is the overall hardness of the piece of cane. Should the measurements be more than 4 apart (i.e. 12 and 17, or 0.12 and 0.17 mm) then that piece of cane is unlikely to produce satisfactory results.

Changing the Battery

Our digital dial indicators and hardness testers run on both LR 44 or SR 44 batteries. Changing these out is quite simple, and we have outlined the steps below for your convenience.

-

-

-

To install or replace the battery, first remove the battery holder from the dial. Take care to lift straight up while doing so to avoid any potential damage.

-

-

-

-

Replace the battery with a new LR 44 or SR 44.

-

-

-

-

Place the battery holder back into the dial, with the longer hook on the right side. Take care to push straight down while doing so to avoid any potential damage.

-

Now that the battery has been changed, your dial indicator or hardness tester is ready to continue providing insight into your reed making process.

Zeroing the Dial

It is important to zero the dial for each piece of cane being measured. This will ensure accurate measurements, and should be done after inserting each piece of cane.

-

-

-

Analog

Rotate the dial so it is reading "0."

-

-

-

-

Digital

Press the "Zero" button.

-

Reading the Hardness

-

-

-

Analog

Read the small red numbers to find the hardness of the cane.

-

-

-

-

Digital

The readout will now read the hardness of the cane.

You can ignore the negative as well as the decimal.

-

The hardness tester measures how far the measuring tip is pressed into the cane. Therefore the following relationship is relevant:

- Smaller numbers = harder cane

- Larger numbers = softer cane